Merrilees Collection, National Archives of Canada, Neg. no. PA204100

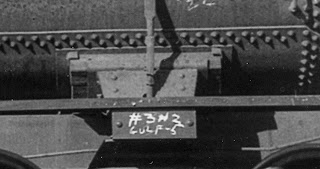

From 1944 to 1951, the Texas & New Orleans added 3,100 gondolas that were based upon the Emergency de- sign 50-ton gondola, substituting wood in place of steel to conserve precious plate steel during the war. However, the T&NO continued to purchase gons that were of composite design even after the restrictions on plate steel were lifted. The cars were assigned to four classes. The data is presented in the accompanying table.

In 1959, the T&NO began to replace the wood sheathing with plate steel. About half of the cars were converted. When so modified, the class number was amended to include an ‘A’ after the original class number, e.g. G-50-19 became G-50-19-A.

For more information, consult Southern Pacific Freight Cars, Volume 1: Gondolas and Stock Cars, by Anthony W. Thompson, Signature Press, 2002.

|

| Bob's Photo |

.jpg) |

| Jim Gerstley |

Why am I presenting this information, beyond its prototype importance? As an SP modeler, I am a T&NO modeler to a certain degree, as well. This is a ubiquitous gon, T&NO or not and Funaro & Camerlengo has produced a nice resin kit for the Emergency gon. Therefore, it's a good fit for me. That said, I intend to modify the kit to accept Detail Associates ends, which are an appropriate end for many of the prototypes, plus use the Scullin L-V trucks from Plate C that were used on T&NO nos. 46300-46549 (250 cars, G-50-21) and 48000-48499 (500 cars, G-50-24) and the National Scale Car decals. The next post will begin chronicling the build. Stay tuned