|

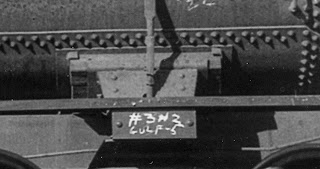

| When converted from auto cars, many of the X28A class cars received spliced doors as illustrated here. Bill used the kit door with a strip of 0.005" styrene and rivets to simulate the splice |

Over the years, Bill and I had been working on several blog posts demonstrating some of his modeling efforts. Unfortunately, many of them will remain as unfinished projects due to the loss of Bill almost two years ago. It seems fitting to share as many of them as I can present, even in an unfinished state, as Bill's detailing was really the heart of his modeling efforts. What follows are some of the things he did to dress up Sunshine Models kits of the X28A and X29. The captions try to explain the images, which, as was usual with Bill's work, speak for themselves.

|

| This is the "stock" Sunshine X29 with many of Bill's upgrades including a scratchbuilt placard on the door |

|

| Bill frequently used wood strips for cars that had wood running boards. He would add many, to be painted the same color as the roof, and leave off a couple to be "unpainted" boards added as repairs. The "missing" boards here would be added after painting. |

|

| The corner grab irons on the roof had a long leg and corresponding hole in the roof, to be used to "pin" the latitudinal running boards in place |

|

| This image shows the lower left corner of the side of the X28A. Details include Tichy rivets at the body bolster, a Red Caboose route card board (from an X29 kit), brass cast bracket grabs (using the Red Caboose X29 parts as masters) and Yarmouth Scale Models sill steps pinned with brass |

|

| Here is the lower right portion of the X28A, including Red Caboose door stops and styrene mounting pads for the ladders |

|

| This is a closeup of the lower left of the side of the X29. The details are similar to the X28A shown above |

|

| The lower right of the X29 |

|

| This image shows the B end of both the X28A, at left, and X29. Note the difference. in height. |

|

| This is a closeup of the brake step and pressure retaining valve on the X28A |

|

| Bill used Red Caboose ladders, but replaced the rungs with 0.010" styrene rod |

|

| Bill added Red Caboose hand wheels with Tichy nut-bolt-washers (NBW) at the top |