Sunday, September 30, 2018

Handling Kadee HGC Trucks

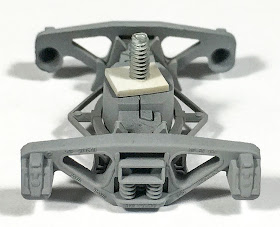

Many of us have welcomed Kadee's High Gravity Compound (HGC) trucks with open arms. They are beautifully rendered representations of useful prototypes, eliminate the toy-like, see-through truck springs, and have a weight near their metal cousins due to the HGC material.

One thing about them that can be maddening is handling them when they are not screwed into a car. They can be like slippery eels as there is nothing holding them together. When purchased as separate trucks, they come with small clips that sit on the screw threads. However, these clips can easily become detached when handling. I am working on painting a pair of sideframes from a PS-1 and came up with a simple solution to keep them together until I get them screwed into the car body. I drilled a hole with a no. 50 drill bit through a piece of 0.030" x 0.188" styrene (although any suitable piece of styrene or even rod will work). I then screwed the truck screw into the piece of styrene. This holds the truck together and allows for handling while I paint and weather the sideframes. Problem solved.

Thursday, September 27, 2018

Scratch Brushes

|

| Scratch brushes: brass, at top, with "bristles" extended and fiberglass, at bottom, with "bristles" retracted |

They are designed to remove buildup of oxidation (and crud) from jewelry. Their proper name is a scratch brush. I ended up ordering one each of the fiberglass and brass variants from Amazon (I am actually an Amazon Prime member to get their data storage, but loathe giving money to

In addition to fiberglass and brass, steel "bristles" are another option. Replacement bristles can be ordered as needed. These tools are about the size and shape of pens. By turning the top of the handle, one can extend or retract the bristles. The shorter the bristles, the more roughly they "score" the surface. After about two strokes across a styrene flat car deck, I realized these are amazing tools for weathering. I cannot recommend them highly enough. I will provide a separate post that highlights some of their capabilities. Until then, buy some of your own and use them liberally.

Wednesday, September 26, 2018

Wordy Wednesday - Pere Marquette 83332

|

| San Diego, California, November 22, 1954, Col. Chet McCoid photo, Bob's Photo Collection |

About the photo... this is the first of what will be many images from Col. Chet McCoid during his wanderings in San Diego. Many of his photos from there were recorded when the light was low and the subjects rendered relatively low contrast and saturated, perfect for highlighting subtleties such as surface details and weathering. Pere Marquette 83332 was built in 1930 by Standard Steel Car Company as part of a group of 1,500 cars, nos. 82000-83499. The cars followed the "Modified" ARA design (based upon 1923 ARA and closely related X29 designs), but with the crossbearers located under the door posts in what would become the "standard" location. This design was ordered by other Van Sweringen roads C&O and Erie, as well. The PM versions used the Hutchins Dry Lading roof, a departure from the cars on their cousins' lines.

Yankee Clipper offered HO scale resin kits of these cars many years ago. They are currently unavailable in the Funaro & Camerlengo line. I am fortunate to have one in my unbuilt kit inventory that will become one of my two "signature" PM cars when I build it. The other is one of the single sheathed automobile cars.

For more about these Pere Marquette prototype box cars, see "Pere Marquette 1930 Steel Box Car" by Jeffrey Koeller in Mainline Modeler, May 2001.

Monday, September 24, 2018

2018 Mid-Atlantic RPM

|

| The largest and most impressive model was the MV Danica Marie as created by host, Bernie Kempinski |

|

| I believe this scratchbuilt structure was the work of Stanley McAdoo... |

|

| ... as was this Norfolk Southern SD70M |

|

| Bernie Kempinski showed off his fine etchings on the sides of these large auto loaders |

|

| Ralph DeBlasi brought several flat cars with interesting loads |

|

| Jerry Dembeck built one of the interesting PFE R-70-2s from a Sunshine kit |

|

| Fritz Dahlin created interesting aluminum bales from the real stuff... |

|

| ... as well as resin interiors for his car models. |

|

| Brad Trenkamp displayed this incredible in-progress model of the American Can Company |

|

| Tom Devenny had a large number of freight cars on display, including this realistically weathered Branchline kit of a DT&I box car |

|

| He also detailed a Con-Cor model of an ACL ventilator, proving that toy trains can be modified into prototypical miniatures, too |

|

| Ted Dilorio conducted a hand-on weathering clinic and had models to illustrate his techniques |

|

| Todd Hermann displayed beautiful models of the CQ Tower and Maintainers' buildings at milepost 97 on the Lehigh Valley in West Catasauqua, PA, circa 1956 |

|

| As always, Bill Hanley shared his highly details B&O models |

|

| Adam Henry flew the banner for N Scale with this Ma & Pa CF7 conversion... |

|

| ... as well as this scratchbuilt model of the lime loadout at the Vulcan Quarry in Hanover, PA |

|

| Butch Eyler held court promoting the virtues of Gouache as a medium for weathering (I agree) |

|

| At an adjacent table, Ted Dilorio and Ralph Heiss also offered hands-on weathering |

|

| Tom Potthast showed some S scale models, including this bridge from castings by Tom Meisner and custom decals for Landsdowne Avenue in St. Louis |

|

| Tom also brought this S Helper SW-9 decorated for Frisco |

|

| Adam Chilcote displayed this Penn Central with a structural load... |

|

| ... as well as this NYC AAR 70-ton flat with highly realistically weathered deck. |

Sunday, September 23, 2018

Revised and Updated "Oddball 40' PS-1 Box Cars" as presented at MARPM

The revised and updated "Oddball 40' PS-1 Box Cars" presentation from the 2018 Mid-Atlantic RPM has been uploaded to the Speedwitch files page. The only change of significance is the work done on the NP 40' combination door car. I am targeting completion for display of the pattern and build work for all but one of the project cars for Prototype Rails (Cocoa Beach).

The "project" cars include:

The "project" cars include:

- CNW automobile car

- SAL AF-4 automobile car

- CNW riveted box car

- at least one 12-panel box car

- NP combination door car (the side illustrated above)

- Southern 9' door opening box car

Thursday, September 20, 2018

Finishing the Litchfield & Madison Gondola

In the last post about modeling the Litchfield & Madison's USRA "clone" composite gondolas, I covered the construction and detailing not covered in my presentation file from the St. Louis RPM. This post picks up from there and highlights the completion of the model.

First, the trucks. I have been going back and forth on the exact manufacturer of the truck bolsters used on the prototype. I am still uncertain. I have waffled between Simplex and Huntoon and other less prominent possibilities. Regardless, the bolsters do have the "box" ends typical of these manufacturers' bolsters. It is a feature I wanted to replicate for a few reasons: it is a prominent detail, it would undoubtedly expand my modeling skills, and it would hopefully provide a solution for future similar needs in the absence of a commercially-available solution.

The sideframes of the prototype were quite similar if not identical to the Tahoe Model Works ARA 40-ton trucks without Barber Lateral Motion details (TMW-115/TMW-215). I used those trucks as my baseline. Through trial and error, I found that 0.040" x 0.125" strip styrene would fill the opening in the truck bolster (I didn't have this on hand, but created it from 0.010" x 0.125" combined with 0.030" x 0.125"). I glued it in place with Walthers Goo thinned 50% with MEK followed by ACC flowed in to fill the small remaining gaps. After it dried, I trimmed it flush using sprue nippers. I then used 0.010" styrene to fill the "wedge-shaped" opening followed by a piece of 0.005" styrene that is 0.125" wide on top of the wedge-shaped piece. I filed all of this so that the face of the bolster was flat. Lastly, I added a piece of 0.010" styrene rod on top (Plastruct offers 0.010" styrene rod). I think the trucks capture the look and feel of the prototype.

I have a pretty standard regimen for finishing models. I sandblast all metal and engineering plastic surfaces, as well as any "shiny" areas on the resin surfaces, to provide a surface conducive to good paint adhesion. This includes the truck sideframes and "faces" on the wheelsets. I use 220-grit aluminum oxide with a Paasche Air Eraser and a blasting booth. I follow the blasting by washing the model and parts with liquid dishwashing detergent (such as Dawn) using a soft toothbrush. All parts are thoroughly rinsed and allowed to air dry.

I "prime" models with a grey paint that isn't necessarily a primer, but provides a base coat and reveals any glaring imperfections that might need to be fixed. On this model I used Tamiya Sky Grey applied with an airbrush. As a side note, it goes down incredibly smoothly and in a very fine coat, which is what I would expect from a "true" primer.

The interior wood surfaces were painted with Tamiya XF-59 Desert Yellow. This is my standard base color for wood surfaces. After the yellow had dried, I masked the interior wood surfaces and applied Tamiya black, with a touch of grey, to the other surfaces of the model, including the interior faces of the ends, trucks, wheelsets, and the couplers. I applied a light coat of Future floor wax, applied with an airbrush, to the sides and ends to create a glossy surface for the decals.

The decals were applied using my standard regimen. Once the decals loosen from the paper backing, I slide them in place on the model. I let them dry before adding any setting solution. I also added several chalk marks that would be "under" the weathering, to replicate some older chalk marks. I did not apply the repack stencils, as they would be added after the weathering, as well. There were a few areas that required gentle slicing and reapplication of setting solution to eliminate trapped air. Once I was satisfied with the decals, I applied a small piece of masking tape to each side of the car where the repack stencils would be placed after weathering. The tape would keep these areas "clean" during weathering, to reflect freshly painted areas.

Using an airbrush, I applied a coat of Tamiya XF-86 clear flat. This served the dual purposes of sealing the decals and creating a flat surface for the application of weathering. I used powders for the weathering. On the interior simulated wood surfaces, I applied Bragdon grimy grey and Panpastel raw umber and extra dark Payne's grey, in that order. On the exterior surfaces, including trucks, I used only the Panpastel raw umber. I added a little Bragdon's rust powder to the couplers. All weathering was sealed with another application of Tamiya clear flat.

I removed the masking tape for the application of repack stencils. Using a fine brush, I applied small amounts of Future floor wax to the areas where the repack stencils and additional chalk marks would be applied. I added these decals followed by another coat of the Tamiya clear flat.

I cleaned the treads of the wheelsets and inserted them into the truck sideframes. I added the couplers to the pockets. I glued small bits of paper to the car sides to simulate route cards. The last detail, unfinished at this point, is to add the angle cock/air hose parts. I am awaiting a replenishment of these as my stash has been consumed.

I am quite happy with this project as it has resulted in a distinctive composite gondola being added to the fleet that has also introduced me to a couple new modeling skills. Mission accomplished.

I am already looking forward to next year's project for the 2019 St. Louis RPM (no teasers yet!)

Tuesday, September 18, 2018

More building the Litchfield & Madison Gondola

This post gets into the meat that I teased on my last post about these cars. It has proven to be an immensely gratifying project. First, I want to highlight a few things I will recommend that others not do or things that I hinted I might do that, in the end, I did not.

I do not recommend modifying the coupler box on the model. It would not be a great deal of work to leave it intact and work around it when adding the ends. It also would not be a great deal of work to remove it entirely before doing any serious modification to the body, in the instance where you wish to add your own different style of coupler box. The "halfway" method, as employed by yours truly, meant that I had to add strip styrene to "complete" the box in the place where I had removed it earlier. See the presentation for more detail.

I also wish to strongly hint that one need not go to the extremes that I did. A fine model with significant detail may be created with less effort.

During the clinic, I intimated that I would do both 0.005" styrene as well as brass to provide two different avenues for the braces in the end panels on the sides. In practice, the 0.005" styrene versions proved far easier to make. I abandoned the brass versions midstream. I suspect that Mylar would be a good compromise.

Most of what follows will be photos with some accompanying text and/or commentary. If you have questions, comments or suggestions, please feel free to post them in the comments section at the bottom of the page.

I posted this image because it serves as a basic view of the underbody components, but is also before paint was applied, allowing the viewer to more easily identify the various materials. These various items are covered in greater detail later in this post. Note that I left the operating rods for the drop doors in place... they're not visible from the side and removing them would have been more effort than worthwhile.

This is the basic view of the side. Note that I used styrene for the side boards. I recommend using the resin side boards as they are quite nice (courtesy of Bill Welch) and the styrene added no appreciable improvement.

I believe this view of the end provides a good view of the various materials used. I will note here that the discs and rivets used on the brass stiles and for the towing loops rely upon the RP Toolz punch and die (see post about this useful tool here).

Brakes can be confusing to model. I hope that this image is worth a 1,000 words. I do not know if this arrangement is 100% correct for this prototype. My assumption is that the arrangement would have been the same for tight bottom cars like this as well as for the drop bottom versions that the L&M retained, as the shops would have liked such consistency (I assume). This arrangement would not foul the drop doors on cars with drop doors so it is what I chose to model.

For the reservoir mounting arrangement, I replicated something I recently saw on a vintage prototype gondola. I have no idea if it is correct for this car, but I wanted to try it.

Similarly, I am unsure if the dead lever was arranged as shown here, but I wanted to try this arrangement in model form. You are welcome to try something different. I used 0.0015" brass in several places on the model. I have a large sheet. I simply cut what I need and then make the necessary bends to meet the application. It is so thin that it can be easily cut in one pass with an Xacto knife. Erroneous bends can be flattened easily and the material simply re-bent. I glue it with Walthers Goo thinned 50% with MEK followed by sparing application of ACC to strengthen the joints.

The towing loops are rather self-explanantory. The corner braces proved to be simpler than I had envisioned. I created strips from 0.005" styrene that are 6 scale inches wide. I glued them to the car sides. I then created strips from 0.005" that are 0.030" wide. These were glued on edge against the edges of the strips that I had glued to the sides. I ran some ACC into the joints where the strips were glued to each other. I created the "scallops" for the lower right grab after I had glued the strips in place. The lower right grab shown (as well as the lower ones on the ends) was made by trial and error. All the grabs on the model were created from 0.010" wire. NOTE: the corner braces should extend all the way up to the top steel side member. I ended mine adjacent to the member, as shown.

I opted to use the lever hand brake included in the kit, but used wire for the "staff" portion. I simply drilled a hole through the hand brake and threaded 0.015" wire through the part.

Watch for another post very soon showing the steps to completion, including modeling the trucks with Huntoon bolsters.

Here is a parts list for the project:

I do not recommend modifying the coupler box on the model. It would not be a great deal of work to leave it intact and work around it when adding the ends. It also would not be a great deal of work to remove it entirely before doing any serious modification to the body, in the instance where you wish to add your own different style of coupler box. The "halfway" method, as employed by yours truly, meant that I had to add strip styrene to "complete" the box in the place where I had removed it earlier. See the presentation for more detail.

I also wish to strongly hint that one need not go to the extremes that I did. A fine model with significant detail may be created with less effort.

During the clinic, I intimated that I would do both 0.005" styrene as well as brass to provide two different avenues for the braces in the end panels on the sides. In practice, the 0.005" styrene versions proved far easier to make. I abandoned the brass versions midstream. I suspect that Mylar would be a good compromise.

Most of what follows will be photos with some accompanying text and/or commentary. If you have questions, comments or suggestions, please feel free to post them in the comments section at the bottom of the page.

I posted this image because it serves as a basic view of the underbody components, but is also before paint was applied, allowing the viewer to more easily identify the various materials. These various items are covered in greater detail later in this post. Note that I left the operating rods for the drop doors in place... they're not visible from the side and removing them would have been more effort than worthwhile.

This is the basic view of the side. Note that I used styrene for the side boards. I recommend using the resin side boards as they are quite nice (courtesy of Bill Welch) and the styrene added no appreciable improvement.

I believe this view of the end provides a good view of the various materials used. I will note here that the discs and rivets used on the brass stiles and for the towing loops rely upon the RP Toolz punch and die (see post about this useful tool here).

Brakes can be confusing to model. I hope that this image is worth a 1,000 words. I do not know if this arrangement is 100% correct for this prototype. My assumption is that the arrangement would have been the same for tight bottom cars like this as well as for the drop bottom versions that the L&M retained, as the shops would have liked such consistency (I assume). This arrangement would not foul the drop doors on cars with drop doors so it is what I chose to model.

For the reservoir mounting arrangement, I replicated something I recently saw on a vintage prototype gondola. I have no idea if it is correct for this car, but I wanted to try it.

Similarly, I am unsure if the dead lever was arranged as shown here, but I wanted to try this arrangement in model form. You are welcome to try something different. I used 0.0015" brass in several places on the model. I have a large sheet. I simply cut what I need and then make the necessary bends to meet the application. It is so thin that it can be easily cut in one pass with an Xacto knife. Erroneous bends can be flattened easily and the material simply re-bent. I glue it with Walthers Goo thinned 50% with MEK followed by sparing application of ACC to strengthen the joints.

The towing loops are rather self-explanantory. The corner braces proved to be simpler than I had envisioned. I created strips from 0.005" styrene that are 6 scale inches wide. I glued them to the car sides. I then created strips from 0.005" that are 0.030" wide. These were glued on edge against the edges of the strips that I had glued to the sides. I ran some ACC into the joints where the strips were glued to each other. I created the "scallops" for the lower right grab after I had glued the strips in place. The lower right grab shown (as well as the lower ones on the ends) was made by trial and error. All the grabs on the model were created from 0.010" wire. NOTE: the corner braces should extend all the way up to the top steel side member. I ended mine adjacent to the member, as shown.

I opted to use the lever hand brake included in the kit, but used wire for the "staff" portion. I simply drilled a hole through the hand brake and threaded 0.015" wire through the part.

Watch for another post very soon showing the steps to completion, including modeling the trucks with Huntoon bolsters.

Here is a parts list for the project:

Givens

- Intermountain USRA Composite Gondola body and details

- Cast resin ends and sideboards

- Strip styrene (for floor boards)

- Decals

Extras

- Styrene - 0.005” plus various strip

- Brass - 0.0015"

- Wire - 0.008”, 0.010”, 0.012”, 0.015”, 0.020”

- Nut-bolt-washer details (Detail Associates)

- Eye bolts (bent from wire, although there are commercial options)

- Chain

- A-Line sill steps

- AB brake components

- Grab irons (ones on model shown herein were bent from 0.010" wire)

- Pressure retaining valve (Precision Scale part used; most brake sets include one)

- Angle cocks/air hoses

- Angle cock/air hose brackets (Yarmouth Model Works part 507)

- Rivets - both from Archer Surface Details and as harvested from models

- Trucks - Tahoe Model Works ARA 40-ton used; no currently available commercial offerings with Huntoon bolsters as used on prototype so I "made" my own

- Couplers

- 0-80 and 2-56 screws

- Paint

Monday, September 17, 2018

Building the Litchfield & Madison Gondola continued

I have finally completed building the Litchfield & Madison gondola that was part of my clinic (link to presentation file) at the 2018 St. Louis RPM. These photos illustrate the model. I will be adding extremely detailed posts over the next couple days to highlight everything I did to build the model, including how I modeled Huntoon bolsters, as seen in-progress here (the white rectangles visible between the truck sideframes). If you were unable to attend the meet, but would like a set of the key parts, they can be ordered via this link.

Friday, September 14, 2018

"The Jack Burgess Files" no. 4: Great Northern single sheathed box car GN 31181

|

| All photos by Jack Burgess, Newark, California, October, 1968 |

The cars were delivered with square corner Dreadnaught ends with three primary corrugations in the top panel over five in the bottom. As delivered, the cars were equipped with unpowered, shaft-style hand brakes. In later years, they were fitted with power hand brakes of both Ajax (seen here) and Universal types. Ladders were used on both the sides and ends.

The Murphy XLA or "Pivoted, Flexible" roof was used throughout the life of the cars, as illustrated here.

As delivered, the cars were equipped with wood doors. Beginning in the 1940s, the GN progressively replaced the wood doors with Youngstown Steel corrugated doors. The wood doors featured a large, front-facing goat emblem. With the replacement of the doors, a smaller emblem was placed between the structural members.

The GN, along with the Seaboard Air Line, was a fairly strong user of the unusual Dalman-Andrews truck, as illustrated here. Note the snubber in the spring package (second of the four springs from the right).

Almost as unusual as single sheathed 40' box cars on the GN, were single sheathed box cars with four diagonal "zee-bar" structural members per side that were arranged in a Pratt truss. The ARA design used "hat" section structural members in a Pratt truss, but the vast majority of similar box cars with "zee-bar" members employed the Howe truss. For early photos of this car, as well as detailed photos of ARA and Howe truss cars, see Focus on Freight Cars, Volume Nine from Speedwitch.

Sunshine Models produced HO scale resin models for these cars as kits 77.1 and 77.2.